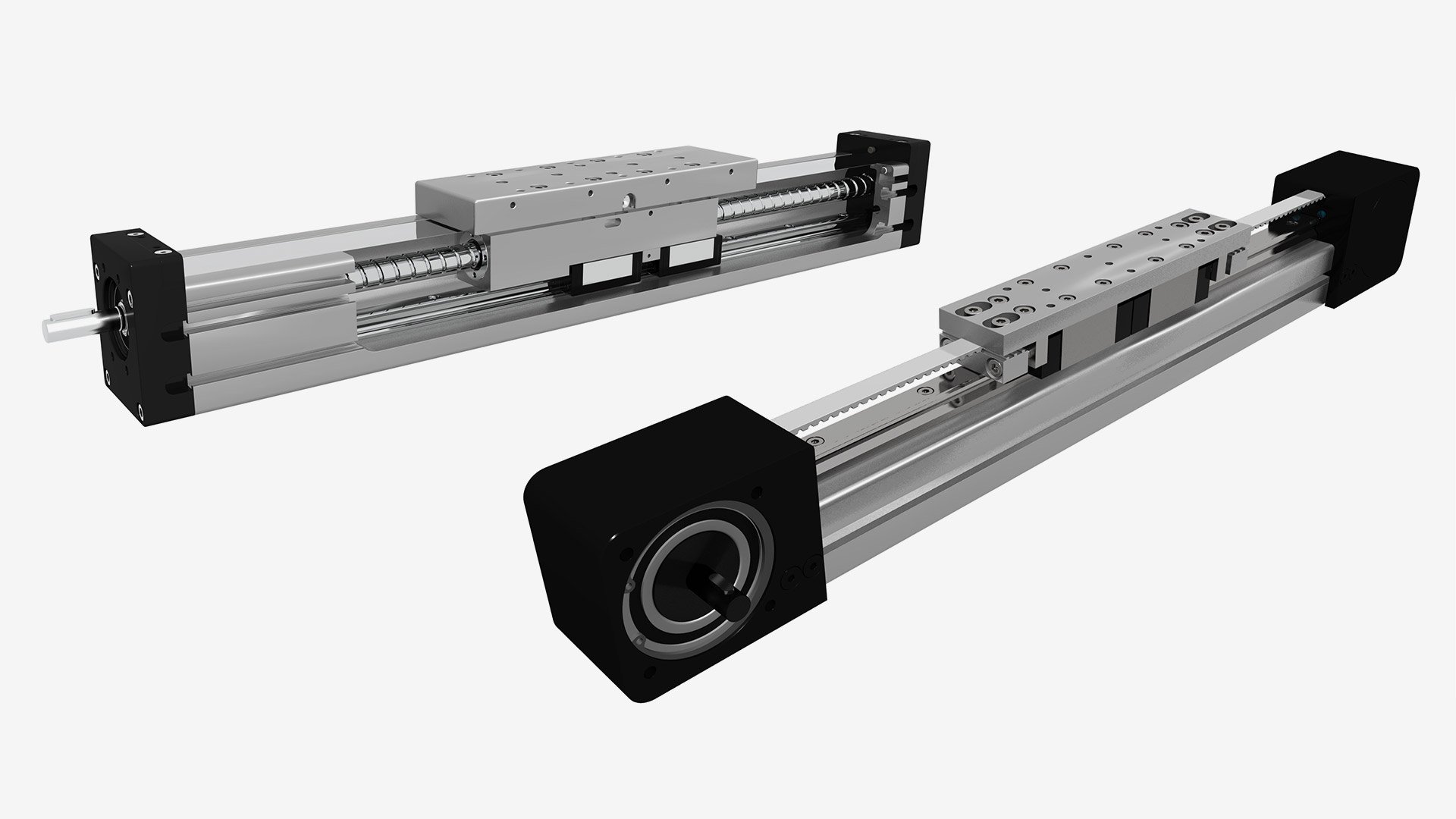

A ball screw driven and a timing belt driven linear unit have different advantages and strengths. Which one you should choose depends on your application's requirements: speed, accuracy, tolerances etc. Rollco's application engineer Pontus Claesson explains the differences and talks about two other unusual solutions.

Advantages and disadvantages of ball screw or timing belt in a linear unit

The ball screw and timing belt have different characteristics that can be beneficial in their way. The application requirements determine which is the best fit.

–If you need high repeatability, stiffness and force, you should choose the ball screw, says Pontus. However, if you need high speed and long movements, the timing belt is a better choice.

Timing belt drive for long fast movements

The timing belt is best suited if you need high speed or fast acceleration. It can be used without any direct restrictions for speeds up to 10 m/s. The timing belt also enables stroke lengths of up to 5-6 meters with good performance and up to 10 meters if you can accept less stiffness and acceleration. However, it has lower precision.

– The timing belt has a much larger feed per revolution and is therefore sensitive to play and loosening in the driving motor and gearbox, says Pontus. But above all, the stiffness of a timing belt is significantly lower than that of a ball screw. So, the actual precision becomes very sensitive to what loads are acting on the driven part.

Timing belt drive is thus better suited for pick-and-place than controlling, for example, a milling cutter that must apply a force.

Ball screw for power and precision

A ball screw can provide a force of up to one ton and is more compact. This means that it works well, for example, in a machining centre where space is limited and the need for high force is great. It has high precision and the repeatability can come down to thousandths of a millimetre with the same position every time. The accuracy is well-defined and can be selected in different classes to about 0.05 mm per meter. In contrast, ball screw drives very quickly lose speed performance when stroke lengths exceed 2-3 meters.

– The ball screw fits well, for example, if you must make an adjustable stop for a sheet metal bending machine, says Pontius. There you may have a movement of one meter which must have a tenth of a millimetre in precision, while at the same time, it must be able to withstand a large force.

Which operation is the best choice?

There is an opinion that in many cases the ball screw is better than the timing belt. But the reality is more complicated than that, Pontus believes.

– For example, the ball screw must be lubricated ten times more often than the wheels in timing belt drive, many people don't think about that. If it is not lubricated often enough, it wears out relatively quickly.

The toothed belt drive, on the other hand, is usually perceived as more affordable, but this is not true either.

– The timing belt drive is somewhat cheaper. At the same time, it needs a downshift that costs about as much as the price difference. The ball screw does not need a gear, which also means that there is one less component to define.

Often the ball screw is perceived as safer than the timing belt in a vertical motion because it is perceived that the belt has a comparatively greater risk of breaking. But if the balls in the ball screw are destroyed or lost for some reason, it will fall freely. At the same time, a properly dimensioned and pre-tensioned belt drive has enormous strength.

– However, it is common to choose a belt drive for horizontal movements and a ball screw for vertical movements.

Rack and pinion and linear motor are less common options

In addition to ball screw driven and timing belt driven linear units, two other options are less common – rack and pinion, and linear motor. The rack and pinion is as stiff as the ball screw and has a stroke length of up to 70 meters, but is difficult to get completely backlash-free. However, it is not until stroke lengths of over 10 meters are required that it becomes competitive.

– For example, it is often used for moving industrial robots over longer distances, Pontus says.

The linear motor is a more extreme variant of linear drive. It has no mechanical propulsion, but a linear-acting motor. As it operates contactless with magnetic power, there is no mechanical transmission that wears out, can break or needs to be maintained and lubricated. It has unlimited stroke length and regulated stiffness. The linear motor combines the speed of the belt drive with the precision of the ball screw and, since its invention 30 years ago, has been predicted to replace them both. But it hasn't happened yet.

– The reason is that it is still a very expensive technology, with expensive engines and components, says Pontus. Today, the linear motor is mainly used in the electronics industry, where in certain moments extreme accuracy is required, both in terms of millimetres and seconds.