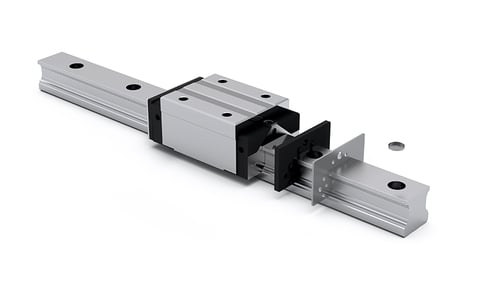

There is a lot to consider when choosing a linear rail guide solution. Many times, you need to supplement with various accessories. The range is broad, and it is not always easy to get an overview of availability and when to use what. We asked one of Rollco's salespeople, Daniel Stifors, about what you need to think about.

A selection of options and accessories for rail guides

Many factors determine which accessories you need to construct a well-functioning linear rail system.

– To achieve a long service life and little need for maintenance, you may need to choose, for example, a preloaded slider or a slider with extra seals. It depends, among other things, on factors such as the surrounding environment and special application requirements, says Daniel.

When do you need a preloaded slider?

Sometimes the construction may require a slider with increased preload, e.g. when there is a need for a vibration-resistant movement or higher rigidity. Ball rail guides have balls in both larger and smaller dimensions. In general, larger balls give higher preload and vice versa. The smaller dimensions provide a smoother movement, while the larger ones provide a more precise movement.

– By increasing the diameter of the balls in the ball circuit, an increased pressure is created on both the rail and the slider. This results in a stiffer and more precise movement, says Daniel. The increased resistance reduces the speed slightly, but the movement is still easy.

Different solutions for lubrication and protection of rails and carriages

There are various accessories to lubricate and protect the linear rail guide, including different types of seals and end caps for the carriages. In environments where it may be difficult to access to lubricate your rail guide, a self-lubricating seal is suitable. It continuously feeds the rail with grease and extends the interval for maintenance.

– Tight seals are used to keep the grease inside the block while keeping the rail dry, says Daniel. It is important in dusty environments, as the particles can otherwise mix with the grease on the rail and form lumps. The tight seals also protect the carriage itself from contamination. Tight end seals are commonly used in, for example, sawmills and paper mills where very fine-grained particles swirl around. There are also various solutions to protect the rail, e.g. plugs that prevent dirt and dust from collecting in the mounting holes.

Gables with steel scrapers protect against larger hard particles, such as welding chips and wood chips, by sweeping them away when they stick to the rail. It is an easy way to extend the life of your rail guide.

– When it comes to the choice between oil and grease, we usually recommend regular ball bearing grease, says Daniel. However, always consider the application as special requirements may affect the choice of grease. For applications in food production, the fat used must be food approved. Therefore, the sliders often need to be degreased and then re-greased with FDA-approved grease before delivery.

Surface protection for rails and carriages

Depending on how stressful the surrounding environment is, the rails can be provided with different surface treatments that extend the service life. In addition to the most common such as e.g. nickel plating and chrome plating, there are usually special treatments that provide extra high corrosion protection.

– Which surface treatment is most optimal is determined by external factors, but also by the construction, says Daniel. For example, some sliders that use grease as a lubricant create a film as it moves along the rail. This thin layer of grease works as surface protection, and thus the rail itself does not need to be stainless.

Since the application's needs and the external conditions determine the choice, it is preferable to choose a competent supplier with a wide range of rails and surface treatments. Then they can also recommend the most suitable type based on the construction and the surrounding environment.

Clamping elements for fixing loads

Clamping elements are an accessory used when there is a need to fix a load on the rail. Depending on the type of application, you can choose a clamping element controlled either manually or pneumatically.

– Pneumatic clamping elements create a higher pressure and can also be controlled remotely, says Daniel. The disadvantage is that the solution can become more complicated as the hoses for the compressed air must follow the movement.

What governs the choice of clamping elements, is the application's need for clamping force and how tightly the load must be locked. It is a good idea to let a knowledgeable supplier analyze the needs, and, based on them, choose the right type of clamping element.

Linear rail guides with balls or rollers?

A common question is whether to choose a linear rail system with balls or with rollers. The answer to that question depends entirely on your application.

– Roller rail guides are particularly suitable for machine applications with high load requirements in combination with high rigidity and high vibration resistance, says Daniel.

Ball rail guides are the most common type, and it works for many if not most, applications. It is usually also a cost-effective solution.